Introduction to O-rings

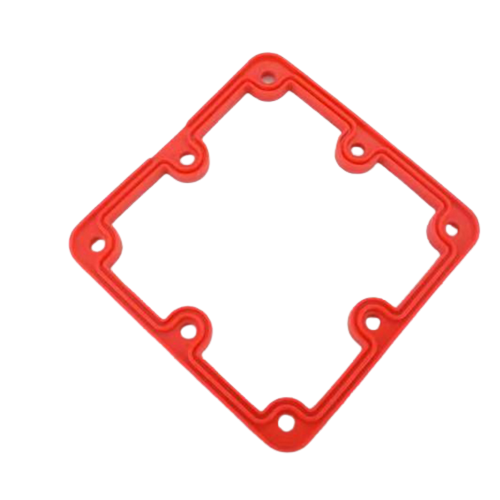

What is an O-ring?

An O-ring is a circular sealing component made of elastomer material, typically rubber or silicone. Its design resembles a donut-shaped loop with a round cross-section. The O-ring's main function is to create a seal between two mating surfaces, preventing the passage of fluids or gases. It achieves this by being compressed between the surfaces, creating a tight and reliable barrier.

Types of O-rings

When selecting an O-ring for a specific application, several factors need to be considered. Let's explore the main aspects to focus on:

3.1. Material Selection

The choice of O-ring material depends on the environment it will be exposed to and the media it will seal. Common materials include nitrile rubber (NBR), fluorocarbon (Viton), silicone, EPDM, and neoprene. Each material has its own unique properties, such as resistance to temperature, chemicals, and abrasion.

3.2. Size and Dimension

O-rings are available in various sizes and dimensions, allowing them to fit different grooves and mating surfaces. The size is determined by the inner diameter (ID), outer diameter (OD), and cross-sectional thickness. Accurate measurement and proper sizing are crucial for effective sealing.

3.3. Cross-Sectional Shape

While the round cross-section is the most common, O-rings can also come in different shapes, such as square, rectangular, and X-shaped profiles. The choice of cross-sectional shape depends on the specific application requirements, including pressure resistance and compatibility with the mating surfaces.

Applications of O-rings

O-rings find extensive use in a wide range of applications across industries. Some common examples include hydraulic systems, pneumatic systems, automotive engines, pumps, valves, plumbing connections, and medical devices. Their versatility, reliability, and cost-effectiveness make them a popular choice for sealing solutions.

Importance of Proper Installation

Proper installation is crucial to ensure optimal O-ring performance. Factors such as correct groove design, surface preparation, lubrication, and compression play a significant role in achieving an effective seal. Careful attention to installation procedures can prevent leaks, premature failures, and system downtime.

Factors Affecting O-ring Performance

Several factors can impact the performance of O-rings in real-world applications. It is essential to consider these factors during the design and selection process:

6.1. Temperature

Extreme temperatures can affect the O-ring material properties, leading to either hardening or softening. It is crucial to select a material that can withstand the intended temperature range to avoid deterioration and loss of sealing effectiveness.

6.2. Pressure

The pressure exerted on an O-ring influences its sealing capabilities. High-pressure applications require materials with excellent compression set resistance and adequate strength to maintain a reliable seal under load.

6.3. Chemical Compatibility

Certain fluids or gases can be aggressive towards O-ring materials, causing chemical swelling, degradation, or loss of elasticity. Understanding the chemical compatibility between the O-ring material and the media it will come into contact with is vital to ensure long-lasting performance.

Common O-ring Failure Modes

Despite their reliability, O-rings can experience failure under certain conditions. Understanding these failure modes can help in identifying potential issues and implementing preventive measures:

7.1. Extrusion

Extrusion occurs when the O-ring material is forced into the clearance gap between the mating surfaces, resulting in permanent damage. This can be caused by excessive clearances, high pressures, or insufficient material hardness.

7.2. Compression Set

Compression set refers to the O-ring's inability to recover its original shape after being compressed for an extended period. It can occur due to factors such as high temperatures, inadequate material selection, or insufficient compression during installation.

7.3. Chemical Attack

Chemical attack happens when the O-ring material reacts with the media it is sealing, leading to swelling, hardening, or degradation. It is crucial to select a material that is chemically compatible with the intended application environment.

Tips for O-ring Maintenance

To ensure the longevity and reliability of O-ring seals, regular maintenance practices should be followed:

Inspect O-rings for signs of wear, damage, or deterioration.

Replace O-rings as part of preventive maintenance schedules.

Clean mating surfaces before reinstallation to prevent contamination.

Apply appropriate lubrication to aid in installation and minimize friction.

Store O-rings in a cool, dry place away from direct sunlight or chemicals.

Choosing the Right O-ring Supplier

Selecting a reputable and reliable O-ring supplier is essential for obtaining high-quality products that meet your specific requirements. Consider factors such as product quality, material certifications, industry expertise, and customer support when choosing a supplier.

Conclusion

O-rings are indispensable sealing components that provide efficient and effective solutions across various industries. Understanding their types, applications, installation considerations, and maintenance practices is crucial for achieving optimal performance and preventing costly failures. By paying attention to factors such as material selection, size, environmental conditions, and proper installation, O-rings can reliably fulfill their sealing duties.

FAQs

Q1. How do I determine the right O-ring size for my application?

To determine the right O-ring size, you need to measure the inner diameter (ID), outer diameter (OD), and cross-sectional thickness. Use calipers or measuring tools specifically designed for O-rings to obtain accurate measurements. Additionally, consult O-ring size charts or reach out to a supplier for guidance.

Q2. Can I reuse an O-ring?

It is generally not recommended to reuse O-rings. Even if they appear undamaged, O-rings can lose their elasticity and sealing properties after being compressed and subjected to temperature variations. It is best to replace O-rings during maintenance or when disassembling components.

Q3. What should I do if an O-ring fails prematurely?

If an O-ring fails prematurely, it is essential to identify the root cause of the failure. Examine factors such as material compatibility, installation procedures, environmental conditions, and system parameters. Making necessary adjustments, such as choosing a different material or improving installation techniques, can help prevent future failures.

Q4. Can I use any lubricant with O-rings?

No, not all lubricants are suitable for use with O-rings. It is essential to choose a lubricant that is compatible with the O-ring material and the application environment. Silicone-based lubricants are commonly used, but it is best to consult the O-ring manufacturer or supplier for specific lubricant recommendations.

Q5. How long do O-rings typically last?

The lifespan of O-rings can vary depending on factors such as the application, operating conditions, and material quality. With proper installation, maintenance, and material selection, O-rings can provide reliable sealing for an extended period, ranging from months to several years.