Backlight Membrane Switch: Enhancing User Experience with Illuminated Interfaces

Introduction

User interfaces play a crucial role in numerous industries, ranging from medical equipment and industrial control panels to automotive systems and consumer electronics. A backlight membrane switch is a specialized interface technology that combines the benefits of membrane switches with backlighting capabilities, providing enhanced visibility and improved user experience.

What is a Backlight Membrane Switch?

A backlight membrane switch is a user interface component that consists of multiple layers, including an overlay, circuitry, backlighting, and adhesive. It is designed to offer a tactile response and control functions while also providing backlighting to enhance visibility in low-light environments. This technology enables users to operate devices efficiently even in dimly lit conditions.

Components of a Backlight Membrane Switch

Overlay

The overlay is the top layer of the backlight membrane switch and acts as a protective cover. It is typically made of materials like polyester or polycarbonate, which offer durability and resistance to wear and tear. The overlay is often printed with symbols, icons, and text that correspond to the switch functions.

Circuitry

The circuitry layer is responsible for transmitting signals from the user's input to the device's electronic components. It consists of conductive traces, usually made of copper or silver, that connect the switch contacts to the device's control circuitry. The circuitry layer is precisely engineered to ensure reliable and accurate performance.

Backlighting

The backlighting element is what sets the backlight membrane switch apart from traditional membrane switches. It consists of light sources, such as LEDs (Light-Emitting Diodes), placed strategically to illuminate the overlay. Backlighting can be customized to different colors and intensities, offering flexibility in design and enhancing the overall aesthetic appeal.

Adhesive

The adhesive layer is responsible for securely bonding the different layers of the backlight membrane switch together. It ensures the durability and longevity of the switch assembly, even in demanding operating conditions. The adhesive should be selected carefully to provide strong adhesion without interfering with the switch's functionality.

Advantages of Backlight Membrane Switches

Backlight membrane switches offer several advantages over traditional switches. Let's explore some of the key benefits they provide:

Enhanced Visibility

The backlighting feature of membrane switches ensures excellent visibility in low-light conditions, making them ideal for applications where users need to operate devices in dimly lit environments. Whether it's a medical device in an operating room or a control panel in an industrial setting, backlight membrane switches improve visibility and reduce the chance of user errors.

Improved User Experience

The combination of tactile feedback and backlighting enhances the overall user experience. The tactile response provides a satisfying feel when pressing the switches, while the backlighting offers visual cues that aid in accurate operation. Users can easily identify the functions and status of the switches, leading to improved efficiency and reduced learning curve.

Customization Options

Backlight membrane switches offer extensive customization options in terms of colors, icons, symbols, and layouts. This flexibility allows manufacturers to tailor the switches to specific applications and branding requirements. Customized backlight membrane switches not only provide functional benefits but also contribute to the aesthetics of the overall product design.

Applications of Backlight Membrane Switches

Backlight membrane switches find applications in various industries. Some common examples include:

Medical Equipment

In medical environments, where precise and reliable control is crucial, backlight membrane switches are widely used. They can be found in devices such as patient monitoring systems, diagnostic equipment, and surgical instruments. The backlighting ensures easy identification of switches, even in dark operating rooms.

Industrial Control Panels

Industrial control panels often operate in challenging environments where lighting conditions may vary. Backlight membrane switches offer excellent visibility in such conditions, enabling operators to control machinery and monitor processes effectively. They are commonly used in control panels for manufacturing equipment, power plants, and automation systems.

Automotive Systems

In automotive applications, backlight membrane switches play a vital role in providing user-friendly interfaces for various functions. From dashboard controls and infotainment systems to climate control panels, backlight membrane switches enhance visibility and simplify user interactions, contributing to a safer and more enjoyable driving experience.

Consumer Electronics

Backlight membrane switches are extensively used in consumer electronics, including mobile phones, home appliances, and gaming devices. The backlighting not only improves usability but also adds an element of sophistication to the product design. Users can easily operate the devices in different lighting conditions without any inconvenience.

Design Considerations for Backlight Membrane

Switches

Designing effective backlight membrane switches requires careful consideration of various factors. Here are some key design considerations:

Light Source Selection

Choosing the right light source is crucial to ensure optimal backlighting performance. LEDs are commonly used due to their energy efficiency, long lifespan, and availability in different colors. The choice of LEDs depends on factors such as brightness, color temperature, and power consumption requirements.

Color and Intensity Control

Backlight membrane switches offer the advantage of customizable colors and intensity levels. Designers should consider the application requirements and user preferences when selecting the backlighting color and intensity. It is essential to strike a balance between visibility, aesthetics, and power consumption.

Uniformity of Lighting

Achieving uniform illumination across the entire overlay surface is essential for an optimal user experience. Designers should carefully position the light sources and consider light diffusing techniques to minimize hotspots and ensure even lighting distribution. Uniform lighting helps users easily identify the switch functions, reducing errors and confusion.

Manufacturing Process of Backlight Membrane

Switches

The manufacturing process of backlight membrane switches involves several steps. Let's take a closer look at each stage:

Printing and Cutting

The overlay layer is first printed with the required graphics, icons, and text using specialized printing techniques. Once the printing is complete, the overlay is cut into the desired shape, ensuring precise alignment with the switch locations.

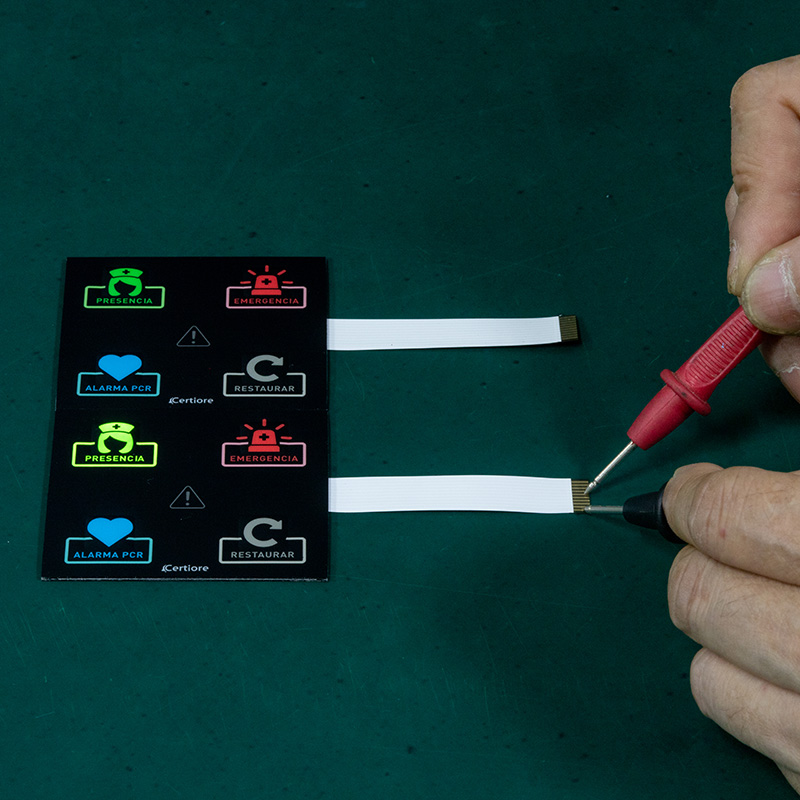

Circuit Layer Assembly

The circuit layer, consisting of conductive traces, is aligned and bonded to the printed overlay. This process ensures the proper connection between the switch contacts and the control circuitry of the device. Careful attention is given to alignment and bonding techniques to maintain the switch's functionality.

Backlight Integration

In this stage, the backlighting element is integrated into the backlight membrane switch assembly. The LEDs or other light sources are carefully positioned, and electrical connections are established to enable backlighting. The integration process ensures that the backlighting is evenly distributed across the switch surface.

Testing and Quality Control

Once the backlight membrane switches are manufactured, they undergo rigorous testing to ensure functionality, reliability, and adherence to specifications. Electrical tests, tactile response checks, and visual inspections are performed to verify the performance and quality of the switches. Only after passing these tests are the switches ready for use.

Maintenance and Care for Backlight Membrane

Switches

To ensure the longevity and optimal performance of backlight membrane switches, proper maintenance and care are essential. Here are some tips:

Cleaning Methods

Cleaning should be performed using non-abrasive, lint-free cloths or wipes. Mild soap or alcohol-based cleaning solutions can be used to remove dirt, fingerprints, or smudges. It is important to avoid using harsh chemicals or abrasive materials that can damage the overlay or the backlighting elements.

Preventive Measures

To prevent damage to backlight membrane switches, users should avoid applying excessive force when pressing the switches. It is also advisable to protect the switches from exposure to extreme temperatures, moisture, and direct sunlight. Following the manufacturer's guidelines and recommendations for usage and maintenance is crucial.

Conclusion

Backlight membrane switches combine the functionality of traditional membrane switches with the added benefit of backlighting. They offer enhanced visibility, improved user experience, and customization options for various industries, including medical, industrial, automotive, and consumer electronics. Designing and manufacturing these switches require careful consideration of factors such as light source selection, color control, and uniform lighting. With proper maintenance and care, backlight membrane switches can provide reliable performance and longevity.

FAQs

1. Can backlight membraneswitches be used outdoors in direct sunlight?

While backlight membrane switches are designed to offer enhanced visibility, prolonged exposure to direct sunlight can affect their performance. It is advisable to protect the switches from direct sunlight and extreme temperature conditions.

2. Are backlight membrane switches customizable in terms of colors and graphics?

Yes, backlight membrane switches offer extensive customization options. They can be tailored to specific branding requirements, including custom colors, graphics, icons, and text.

3. Are backlight membrane switches suitable for waterproof applications?

Backlight membrane switches can be designed to offer varying levels of water resistance. By incorporating appropriate sealing techniques, they can be made suitable for waterproof applications.

4. How long do backlight membrane switches typically last?

The lifespan of backlight membrane switches depends on factors such as usage conditions and quality of materials used. When properly maintained and used within specified limits, they can last for several years.

5. Can backlight membrane switches be retrofitted into existing devices?

Yes, backlight membrane switches can be designed to fit specific dimensions and interfaces, allowing for retrofitting into existing devices. However, it is important to consider compatibility and integration aspects during the design process.